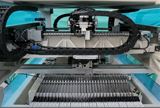

BA684V4 SMT Pick & Place Machine

![[field:title/]](/uploads/allimg/130313/1-1303131Q2580-L.jpg)

FEATURES

- With the two rows of dual-heads (4 multi-heads in total), both rows of heads can pick up the components, and place the components steadily in alternation.

- By using „Closed Loop“ Servo motors with non-contact Linear Encoder System, provide extremely high repeatability and stability.

- Feature COGNEX® vision processing and head-mounted for non-contact „Vision on the Fly” alignment. The machine BA684 assures high-precision placement of the full range of SMDs components.

- During production the user is able to change all 48 x 8 mm Feeders by rapidly changeable Feeder Trolley at the same time..

- Beside the standard fiducial mark, either square SMD PCB pad or plate-through hole also can be trained as fiducial mark.

- A Bottom Vision Camera is used for large components up to 150 x 100 mm and devices with alignment features on their bottom side.

SUMMARY

Dual Gantry 4 Heads

High Accuracy and high Flexibility for

- 0201 (0.6mmX0.3mm)

- SOIC, PLCC

- BGA, μBGA,CSP

- QFP (up to fine-pitch 0.3mm)

Smart Feeder System provides Automatic feeder position checking,Automatic component counting, Production data Traceability

Perfect for small & medium volume production

COGNEX® Alignment System “Vision on the Fly”

Bottom Vision Alignment System for fine pitch QFP & BGA

Built in Camera System with Auto Smart Fiducial Mark Learning

Vision Inspection before and after production

Universal CAD Conversion

Windows XP Software

SPECIFICATION

| Number of Heads (Vision on the Fly) : | BA684V4: 4 |

| Placement rate (under the optimum condition) : | BA684V4: 10’500 CP/H (IPC 9850) |

| Feeder capacity (8 mm) with conveyor : | up to 96 Tape Feeders |

| Feeder capacity (8 mm) with conveyer & optionalFeeder Rack Trolley : | over 96 Tape Feeders |

| IC Tray capacity : | up to 2 Waffle Trays |

| Component Sense : | Vision detection |

| Component Size : |

Handled by head camera :- Smallest: 0.6 x 0.3 mm - Largest: 16 x 14 mmHandled by fixed Bottom Vision Camera :- Smallest: 0.4 x 0.2 mm (option) - Largest: 150 x 100 mm (option) |

| Resolution : |

X / Y axis 0.05 mm Servo Motor Z axis 0.02 mm Servo Motor |

| Rotation : | 0 to 360° (0.045°/step) Servo Motor |

| Placement Accuracy : |

+/- 0.04 mm +/- 0.03 mm (by optional linear encoder) |

| X-Y Repeatability : | +/- 0.01 mm |

| Placement Area : |

With included 3-stage-conveyor, 2x 32 port Feeder RackMax. 650 x 420 mm (w/o IC-Tray) Max. 650 x 350 mm (with 1x to 2x IC-Tray) Max. 650 x 280 mm (with 3x to 4x IC-Tray) |

| Programming : | Direct input, Vision teach-in, CAD Access (Option) |

| Main Control : | Industrial PC |

| Power : | 240 V / AC - 3810W |

| Pressure : | 75 psi (5.5 bar) |

| Machine Size : | 1210 x 1550 x 1430mm (L x W x H) |

| Weight : | 1340 kg |

* We reserve the right to make changes without notice.

Dual Gantry 4 HeadsWith the two rows of dual-heads (4 multi-heads in total), both rows of heads can pick up the components, and place the components steadily in alternation. The alternating Pick & Place action eliminates idle time and allows maintain the high-speed mounting.

Dual Gantry 4 HeadsWith the two rows of dual-heads (4 multi-heads in total), both rows of heads can pick up the components, and place the components steadily in alternation. The alternating Pick & Place action eliminates idle time and allows maintain the high-speed mounting. Strong and rigid mechanical designBA684 using welded steel frame which guaranteed a strong and rigid mechanical design. Preloaded Ball Screws with Servo Motor system provides high Speed, Repeatability and Stability.

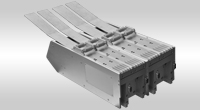

Strong and rigid mechanical designBA684 using welded steel frame which guaranteed a strong and rigid mechanical design. Preloaded Ball Screws with Servo Motor system provides high Speed, Repeatability and Stability. Feeder Rack TrolleyDuring production the user is able to change all 48 x 8 mm Feeders by rapidly changeable Feeder Trolley at the same time.

Feeder Rack TrolleyDuring production the user is able to change all 48 x 8 mm Feeders by rapidly changeable Feeder Trolley at the same time. Bottom Vision Alignment SystemA Bottom Vision Camera is used for large components up to 150 x 100 mm and devices with alignment features on their bottom side. Due to additional Bottom Vision Camera, the alignment of 01005 components is guaranteed.

Bottom Vision Alignment SystemA Bottom Vision Camera is used for large components up to 150 x 100 mm and devices with alignment features on their bottom side. Due to additional Bottom Vision Camera, the alignment of 01005 components is guaranteed. Universal IC Tube FeederKFTB universal tube feeder are using vibration driven technique. It is able to handle IC-Sticks with max.50 mm width.

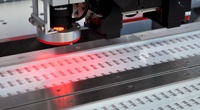

Universal IC Tube FeederKFTB universal tube feeder are using vibration driven technique. It is able to handle IC-Sticks with max.50 mm width. Conveyor SystemThe already included conveyor system with SMEMA Interface and motor-driven-width-control speeds up the handling of PCB and in-line production.

Conveyor SystemThe already included conveyor system with SMEMA Interface and motor-driven-width-control speeds up the handling of PCB and in-line production. Dispenser system available as optionOptional stand alone dispenser head for adhesive & solder paste dispensing. Perfect for quick, small volume production without making stencil.

Dispenser system available as optionOptional stand alone dispenser head for adhesive & solder paste dispensing. Perfect for quick, small volume production without making stencil. IC Tray HolderThe TS-1 provides adjustability for wide variety of smaller matrix tray and waffle pack combinations and can easily be modified for custom tray configurations.

IC Tray HolderThe TS-1 provides adjustability for wide variety of smaller matrix tray and waffle pack combinations and can easily be modified for custom tray configurations. Universal CAD ConversionBeside the direct input of data by teach-in camera, an optional CAD conversion program for directly transfer of CAD generated pick and place data is available.

Universal CAD ConversionBeside the direct input of data by teach-in camera, an optional CAD conversion program for directly transfer of CAD generated pick and place data is available.